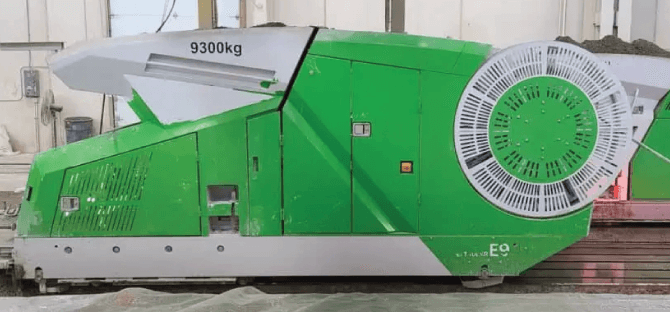

Meet the Elematic Extruder E9: Revolutionizing Molin’s Precast Production

On October 1st, 2021, Molin’s precast concrete facility in Lino Lakes, MN upgraded its casting machinery. The improvements are staggering. Our quality and speed of casting have improved drastically because of the new Elematic Extruder E9 casting machine. Currently, Molin Concrete Products is using the E9 to cast 12” light, 12” heavy, and 12” extra heavy hollow-core concrete planks.

Elematic’s new Extruder E9 sets new records for high-speed casting and hollow core slab production. The machine casts with shear compaction. Concrete mix is poured into a set of screws, pushing it downwards in the machine. The precast concrete is extruded, creating pressure and shearing stress as it compacts the mix.

Molin has used shear compaction for hollow core production for years. The new E9 concrete extruder does shear compaction like no other. As a result, our production speed and hollow core capabilities have soared. All of our staff agree that the purchase has enabled us to better supply precast building systems to the 7-state Midwest region of the US.

The E9 casting speed is 25% faster

The casting speed of the Elematic Extruder E9 is unbeatable. The E9 casts hollow core at 8-9 ft/min. Before, we were casting at 5-6 ft/min. We can now lay eight beds of material instead of six. Stripping two additional beds increases the number of hollow core planks Molin can produce in a day, meaning slabs are ready for installation quicker. Project scheduling is tight. The Extruder E9 helps us to better meet customer timelines.

The speed of the E9 concrete extruder is thanks to the new independent extruding screws. Each screw has a separate drive. They work together to balance the process, leading to faster, higher-quality casting. The Molin manufacturing team notes that the new design of the screws has made the casting more efficient, and the hollow core quality is beautiful.

But the 25% production increase isn’t only because of the independent screws. As the machine casts, it has an interface that automatically monitors and controls the process to maintain a consistent extrusion. The E9’s internal tech optimizes the compaction to feed more concrete and reduce braking.

Hollow core production of the finest quality

As mentioned, the quality of the concrete stunned Molin’s manufacturing team. The E9 is built with a new bouncing prevention system to prevent pressure fluctuations and waves on the surface of the concrete. This leads to a smoother and more evenly cast hollow core. The compaction from the screws is also higher because they are independently driven, so the slabs are denser and stronger.

The user interface makes troubleshooting quick

If that wasn’t enough, Molin’s new Extruder E9 has a 15.6” touch screen designed and programmed with the operator in mind. There are numerous options to adjust different factors as needed. Settings can be adjusted while the machine is still casting so production can continue. It will even alert us if there is an issue with the machine, explaining what is wrong and how to fix it.

Molin’s new casting machine is easier to operate but also safer. We can see how much concrete is in the buckets and the amount still required for the cast on the user interface. This removes the need for operators to look inside the buckets themselves, preventing possible injury. The E9 was made with safety and peak casting performance in mind, truly revolutionizing the hollow core production at our Lino Lakes facility.

Maintenance is simpler than ever

The design of the Elematic Extruder E9 is impressive as well, with more parts in the independent screw motors and bottom of the machine than in previous extruders. Repairs and replacements are easier with multiple parts instead of one, not that the new E9 needs maintenance yet.

The phenomenal design even includes an electronic adjustment of the strand guides. On the old machines, screws could drop in height as parts wore down. The dropped screws would cause slab issues.

The new design prevents this by supporting all screws at the same height with a wear-resistant plate. A better-designed concrete extruder means a better hollow core product, a happier team, and faster results. The Lino Lakes, MN team is happy enough that they can work without earplugs and talk instead of shouting with the new ultra-quiet machine.

Supporting the Future of Precast

Molin Concrete Products would not hesitate to recommend the new Elematic E9 to other precast manufacturers. With the fastest casting on the market, our 12” hollow core planks are better products for our customers and are produced in a timelier manner. For 125 years, Molin has diligently supported and applauded precast innovations. The Elematic Extruder E9 is no exception.

Learn more about Molin’s machines by reading about our newest crane.

Need hollow core slabs or another precast concrete product?

Now an essential part of our process, the E9 could be used on your next project.